The Evolution of Soil Treatment: Embracing Change for a Stable Future

Soil treatment has a long history in construction, improving project soils and ensuring the stability of the pavements and structures built upon them. The practice of soil treatment dates back to ancient times, but it wasn’t until around 1945 when a significant leap occurred. It was then that lime, specifically quicklime, was introduced to the United States as a means to stabilize expansive clay soils for the construction of canals, highways, and airports. This method proved effective in adding strength and reducing or even eliminating soil expansion, marking the beginning of modern soil stabilization techniques.

Let’s work together.

The Emergence of State-of-the-Art Equipment

For most of the 20th century, treating soil with chemical was a rudimentary process, often utilizing farm or other construction equipment such as fertilizer spreaders, disc harrows, motor graders, and small backhoes. Although these tools have their use, they are not specifically designed for soil stabilization, and led to inconsistent mixing, spreading and overall less effective soil treatment. The process was labor-intensive and time-consuming, often resulting in uneven distribution of the chemical stabilizer.

This is no longer the case today; the introduction of modern soil spreaders and reclaimers over the past couple of decades has transformed the landscape, and the benefits that they bring to a project cannot be understated.

The Modern Spreader

The application of chemical treatments in soil stabilization has undergone changes that provide a significant advancement in precision and efficiency. Up until the late 1990s, the predominate method for applying treatment materials involved dumping (e.g., bottom dropping) directly onto the soil. This method was imprecise, leading to uneven distribution and requiring additional labor to spread the materials using motor graders or dozers. The lack of precision not only affected the quality of soil stabilization but could also lead to other concerns, such as increased dust generation and areas of both excess and inadequate application due to fluctuations in the terrain.

Today, the industry has shifted towards more sophisticated, fully automatic methods that provide high-precision, even-spreading of chemical treatments. This ensures that the agent is discharged precisely, independent of the machines’ travel speed. Additionally, pneumatic dust-free loading systems have replaced open dumping, virtually eliminating airborne dust while the use of shrouds and vacuum systems further suppress dust generation during distribution.

The Modern Soil Reclaimer

Modern soil reclaimers are designed with power and integration in mind. These machines typically boast over 500 horsepower to create a homogenous blend of soil and chemical stabilizer by utilizing engineered cutting teeth and mixing drums that penetrate the soil to optimal depths. The high-powered mixing action ensures that the chemical stabilizer is evenly distributed within the soil, typically to depths of 12 inches or more, eliminating the risk of poorly mixed pockets of chemicals or neglected areas that can compromise the structural integrity of the treated soil.

This action is complemented by the ability to inject water directly into the mixing chamber, allowing for precise moisture control, which is crucial for the hydration reaction of quicklime as well as achieving the optimum moisture content for compaction.

Increased Productivity

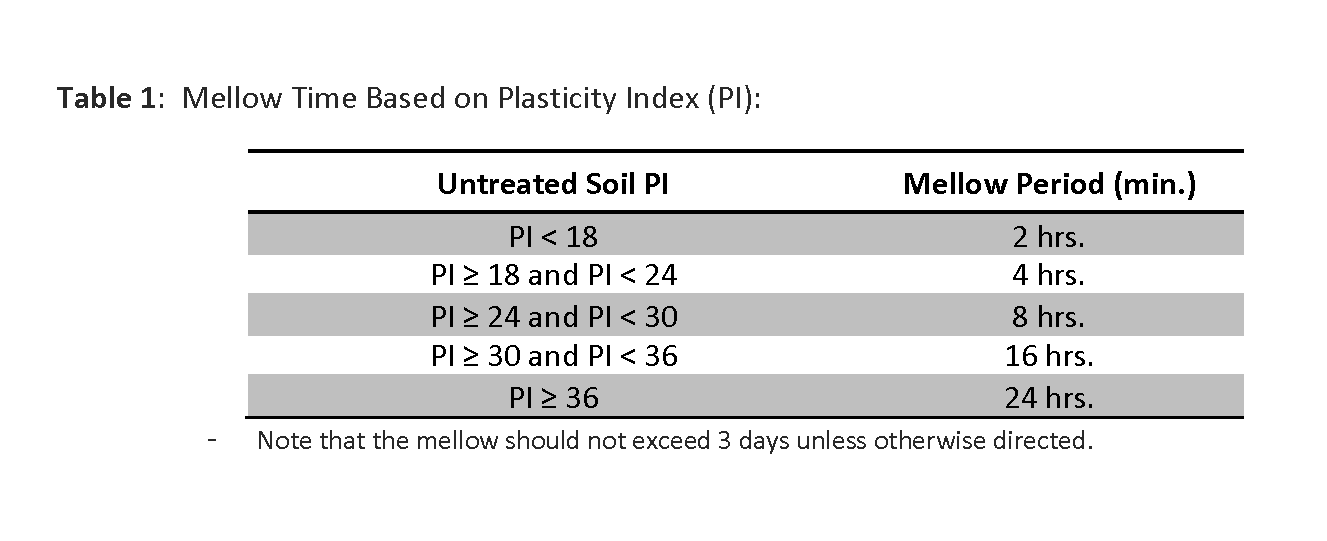

Prior to the use of modern soil reclaimers, lime treated soils were often required to mellow for 24 hours or longer to account for the likelihood that those more primitive mixing practices could result in pockets of poorly mixed chemical, which needed the extra time to fully hydrate and additional mixing to react with the soil; this is no longer required for most soils. The thorough mixing provided by these machines thoroughly pulverizes the soil and distributes the lime, accelerating the soil-lime chemical reactions (mellow period1) by facilitating the hydration and soil modification processes throughout the treatment area. While the duration of the mellow period can vary (generally proportionally to the plasticity index2 of the soil), studies show that when the lime is properly incorporated, the time required to modify a soil and significantly reduce its swell potential is significantly less than 24 hours for all but the most extreme plastic soils, per the following table.

Another benefit of modern reclaimers’ advanced mixing capabilities is that they can eliminate the need for a second pass following the mellow period, particularly in low-to-moderately plastic soils. These benefits allow contractors to work faster and more efficiently, moving on to subsequent stages of the project without unnecessary delays.

Adapting Specifications to the Technological Advancements

State specifications serve as a benchmark for quality and safety in construction. As such, they must evolve with industry advancements, including the benefits brought by modern soil mixers, to ensure that the standards reflect the best practices and technologies available in the industry today.

This evolution allows contractors to plan and execute soil stabilization tasks with greater confidence in compliance and performance which leads to more efficient project timelines, reduced costs, and improved outcomes.

If you have any questions regarding this blog, a soil-treatment specification, or a stabilization project, please reach out to Mintek Resources at (937) 431-0218.

Definitions:

(1) Mellow Period: The mellow period refers to the time allowed for the soil-lime mixture to undergo various physical and chemical reactions before compaction or further treatment. It is during this period that quicklime hydrates and reacts with the soil to reduce its plasticity, improve its workability, and increase its strength.

(2) Plasticity Index (PI): The plasticity index is a measure of a soil’s plasticity. The PI is a measure of how much water a soil can absorb when it changes from a semi-solid (plastic limit) to a liquid state (liquid limit). The PI is expressed as a percentage of the soil’s dry weight and is calculated using the formula:

Plasticity Index = Liquid Limit – Plastic Limit.

We're here to help you find the best solution for your next project. Let's get started. Give me a call at 937-641-9901.

Josh Weser

Mintek Resources

Related Posts

Save Time and Money with Mintek’s Lime Stabilization Calculator

Lime stabilization turns challenging soils into durable foundations suitable for the construction industry. When lime-based reagents interact with soil, a chemical process alters its characteristics - binding clay particles, reducing plasticity & shrink-swell...

Celebrating 30 Years of Excellence: A Toast to Mintek Resources

As we raise our glasses to commemorate three decades of unwavering commitment to our customers, partners and employees, we find ourselves reflecting on the remarkable journey that has brought us to this milestone. Mintek Resources, founded in 1994, has been an expert...

Flexible Packaging and Delivery Options

Purchasing the correct amount of material is just as important as selecting the correct product for your jobsite, which means having a variety of packaging and delivery options is key. With multiple shipping points across the United States and an expert logistics...