Soil Compaction: Methods, Meaning, and Effects

What is Soil Compaction?

Soil compaction is the practice of applying mechanical compactive effort to densify a soil by reducing the void space between soil particles. Compaction occurs when particles are pressed together to reduce the space between them. Highly compacted soils contain very few spaces resulting in soil with higher unit weight. Maximum density is achieved at an optimum moisture content, or OMC, for short.

The process of compaction decreases the likelihood of settlement after a building, roadway, runway or parking lot is constructed. Settlement could result in premature pavement failure, costly maintenance or repairs.

Why is Soil Compaction Necessary?

Soil compaction is necessary to increase the bearing capacity and stiffness of in-situ (natural state) or chemically modified soils. Compaction increases the shear strength of soils by adding friction from the interlocking of particles. Future settlement of soils is reduced by increasing the stiffness and eliminating voids creating a densified soil. The removal of voids reduces the chance of the soil settling or shrinking or expanding and it decreases water seepage that would lead to deleterious shrinking and swelling soil properties. Shrink / swell properties compromise the pavement structure thereby leading to premature failure of the pavement structure.

Get back to work with less downtime.

What Factors Affect Soil Compaction?

Type of Soil

Different types of soil respond differently with respect to compaction. Soils are classified by their particle size and, in some soil categories, by their critical water content values or Atterberg limits. Well-graded granular soils that contain a wide range of particles are preferred in construction applications because they can be easily compacted, thus eliminating voids by interlocking the particles and resisting moisture absorption thereby allowing the soil to support heavier loads as a very dense soil. Poorly graded soils contain a narrow range of particle sizes and are less conducive for construction purposes due to the fact that the soil lacks shear strength, not associated with the non-interlocking particles because of their similar sizes.

Moisture Content

Water content plays a very important role in soil compaction. The maximum dry density is only achieved when the water content is at an ideal level. This point is known as optimum moisture content or OMC. Optimal moisture content and maximum dry density are determined in a laboratory and are then used as targets for on-site operations. If the soil is too dry, water trucks can be deployed to spread water in order to raise the water content within the acceptable range of optimal moisture content. Conversely, overly wet soils present their own set of problems. Recent rain, spring thawing or soils that retain moisture can be handled in a number of ways.

- Waiting on warm, dry weather conditions is the natural way to dry soils but can be time consuming and often ineffective because of (additional) inclement weather.

- Disking equipment, to help aerate soils, can reduce the amount of moisture but this method also opens the soil up to absorb even more moisture in the event of additional rain events. Moreover, disking will typically only reduce the moisture up to 5% and only to relatively shallow depths.

- Cut and fill, also known as remove and replace, is a popular option but is expensive and time consuming. Borrow pits are becoming more and more scarce and disposal costs continue to escalate.

- The most effective option is chemical drying. Portland cement can be used to dry soils but lime-based reagents are pound for pound the most effective chemical choice. Lime-based reagents contain a high amount of available calcium oxide, as high as 94-96 percent. Calcium oxide chemically combines with water, forming calcium hydroxide. More simply put, when lime is around water it absorbs it. This is an exothermic reaction that dries off additional moisture in the form of steam. Portland cement, in principle, will have almost no free lime as the CaO will combine to form other mineral phases.

Types of Compactors

Soil compaction rollers come in a variety of styles with different options such as single or double drums, vibratory mechanisms or dozer blades.

- Smooth rollers use static pressure, sometimes in conjunction with vibration and impact, to compact soil. Smooth rollers are not the only type of compactor utilized, but more than likely used in the final compaction step to provide a smooth surface for construction.

- Padfoot and Tamping foot rollers use manipulative force to break the natural bonds between particles for better compaction, especially in cohesive soils. They have tapered feet so they do not fluff the soil decreasing the ability of soil to absorb additional moisture should it rain.

- On small to medium soil compaction jobs, pneumatic rollers use staggered rubber tires with varying pressure where the surface of bladed granular base materials need to be sealed.

- In confined zones a rammer can be used to densify soil.

Thickness of Lift

Soil compaction sometimes involves compacting multiple lifts, or layers of soil, until the overall desired thickness is achieved. The stability of each lift depends on the one below it so compaction of each layer is critical and must be monitored. Establishing the correct lift thickness is important to find the balance between layers that are too small or too large. A lift that is too large could result in poor compaction and compromise stability whereas a lift that is too small would result in excessive costs and time. Lift thickness typically range from 8 to 14-inches depending on specifications.

Contact Pressure

Contact pressure between the soil and equipment used for compaction is also important to realize. Contact pressure is effected by the overall weight of the compaction equipment and the area of soil contacted by the equipment. The higher the contact pressure the more compaction that is achieved.

Speed of Rolling

When discussing the speed of soil compaction there is a dichotomy to be considered. Faster compaction speeds will allow more area to be compacted. However, if compaction is conducted too quickly there may not be enough time for the necessary deformations to take place. In this case, additional passes would be required to complete the compaction process. Slower equipment traveling speeds are often deemed necessary, especially when using vibratory equipment. Slower speeds of vibratory equipment allow more time for additional vibrations at a given point resulting in better compaction. Compaction equipment usually have travel speeds between 5 and 15 mph. Smooth drum rollers typically move 5 to 7 mph and Padfoot rollers move 5 to 15 mph. Pneumatic rollers can operate at speeds of almost 15mph.

Number of Roller Passes

At a high level, the number of passes needed to achieve desired compaction depends on the contact pressure and speed of the equipment. Factors, such as soil type, moisture level, lift thickness and the type of compactor are also important. In general, a lighter piece of equipment that has less contact with the soil would need a higher number of passes over the same soil to achieve the desired density versus heavier equipment with a larger contact area. However, there is a point where more weight and/or a lower travel speed will have diminishing returns. Operating a heavy compactor very slowly is not necessarily the most efficient option. Typically, a test section can be used to determine the roller pattern that works for the mentioned variable above.

How Does Soil Classification Affect Soil Compaction?

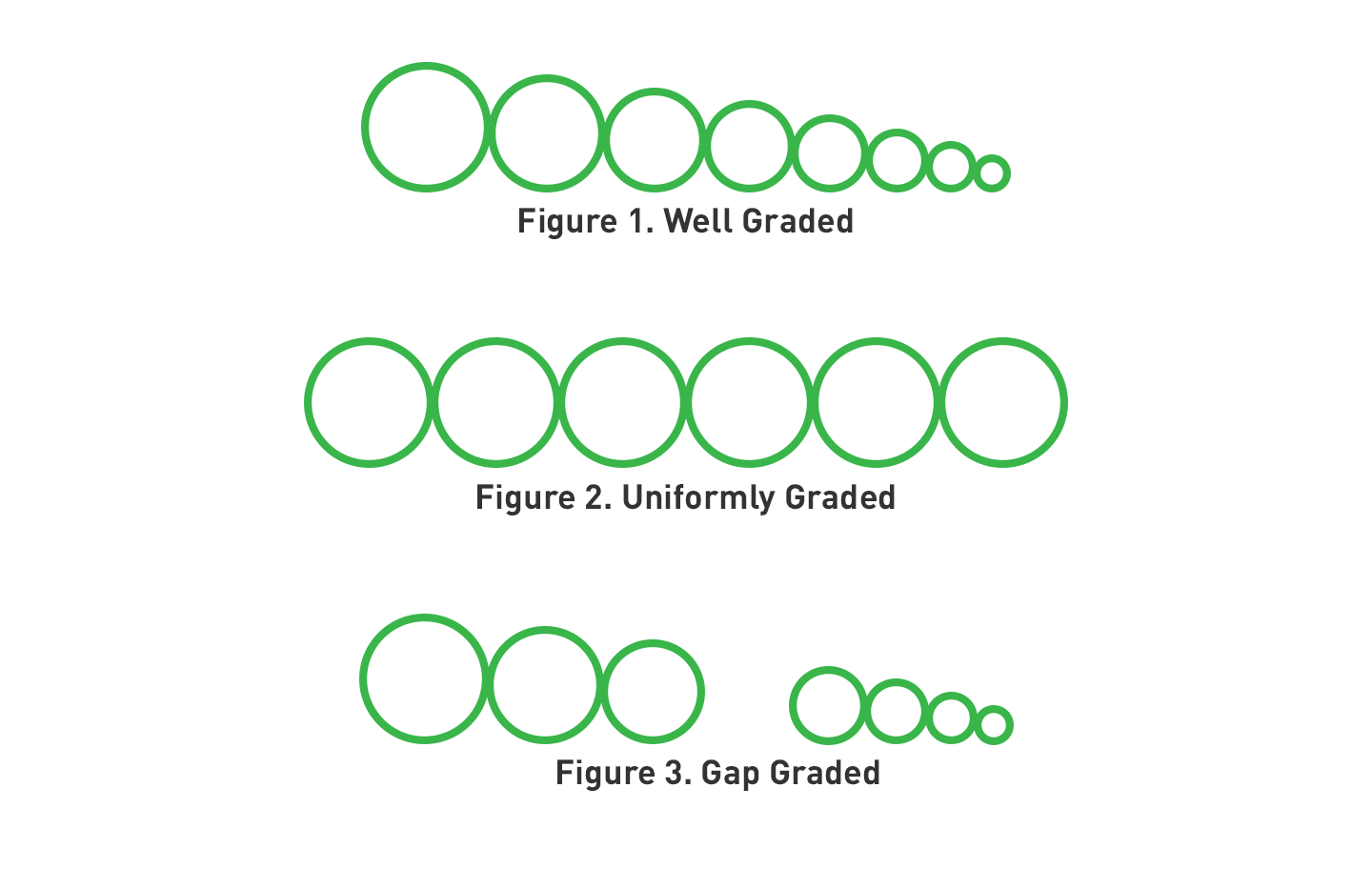

Particle size and critical water values play a large role in soil compaction. Different soil types react differently to compaction efforts. Soil types are classified by their particle size and, in fine-grained soils, by their Atterberg limits. Particle size is determined in a laboratory by separating a representative sample on a series of sieves, or screens, ranging from 4.75 mm (4-mesh) to 0.075 mm (200-mesh). Distribution of soil particles are either well graded, poorly graded or gap graded. Well graded soils that contain a wide range of particles are preferred in construction applications because they can be easily compacted, eliminating voids, interlocking the particles and resisting moisture absorption allowing the soil to support heavier loads as a very dense soil. Poorly graded soils contain a narrow range of particle sizes and are less conducive for construction purposes as shear strength is not associated with the non-interlocking particles because of their similar sizes. Gap graded soils contain a break in the overall distribution of grain sizes.

Soils are classified into two major divisions, coarse and fine-grained soils.

Coarse grained soils have 50% or more larger than 0.075 mm (200-mesh)

- Coarse-grained soils can be further dived into two sub divisions, gravel or sand.

- If 50% of the sample is larger than 4.75 mm, the soil is classified as gravel.

- If 50% of the sample ranges between 4.75 mm and 0.075 mm, it is classified as sand.

Fine-grained soils have 50% or more smaller than 0.075 mm.

- Fine-grained soils can also be separated into two subdivisions, silt and clay. Silt particles are larger than clay particles, which are less than 2 microns.

- However, the formal distinction involves water content and is determined by the Atterberg limits of the soil.

- Atterberg limits are the critical water content values of a soil, which are the liquid and plastic limits.

- The liquid limit is the water content at which fine-grained soils starts to exhibit liquid properties i.e. the ability to flow like a liquid.

- Similarly, the plastic limit is the water content at which a soil starts to exhibit plastic properties i.e. the ability to be remolded without cracking.

- These limits are used to determine the plasticity index of a soil or the range of water contents where a soil exhibits plastic properties, a valuable geotechnical measure.

What are the Different Methods Used to Compact Soil?

There are several methods used to compact soil. All methods involve a static and/or dynamic force along with manipulation of the soil. Static force uses the pressure of a weight to physically and continuously compact soil. Manipulation, such as kneading or shearing the soil in alternating movements, can compact soil at greater depths. In conjunction with pressure and manipulation, dynamic force can be applied by adding a vibrating mechanism. Vibratory compaction methods use different amplitudes (the amount of movement on an axis) and frequencies (the speed of the movement) to apply force in alternating directions, usually by the use of a rotating weight, to deliver rapid blows to the surface. This rearranges the soil particles so compaction not only occurs at the top layers but also in the deeper layers of the soil. Another dynamic method of soil compaction is impact compaction using a falling weight. This method is capable of compacting soil at deeper depths as well.

How is Soil Compacted?

Soil compaction is achieved through static or dynamic force and manipulation of the soil. Static force make use of the dead weight of machines to apply downward, continuous pressure to increase compaction through compression of the top of the soil. Dynamic force uses movement in the form of vibrations or falling weight in conjunction with the static load of the machine to increase the density of the soil. Manipulation through kneading and shearing, helps to compact soil at greater depths.

How do you do a Soil Compaction Test?

Several compaction testing methods can be used to determine the degree of compaction. Preliminary in-situ testing at the project site is important to understand what conditions are present initially. Sand cone testing, the use of a balloon densometer or Shelby Tube are all viable options but most commonly a nuclear density gauge is utilized to test for compaction in the field (ASTM D6938-08a). Laboratory methods generally involve compacting soil into molds at to obtain the soil density. For example the moisture density test (commonly referred to as the Proctor tests) (D698 and D1557) specifies compacting soil in a specified volume mold using standardized weight from a specified height. These requirements make for a controlled and reproducible amount of compacting force and provide the maximum density and optimum moisture content of a soil.

What Does 95 Percent Compaction Mean?

95 percent compaction means that the soil has been compacted to 95 percent of the possible density of the soil through compactive efforts. Maximum dry density, along with optimum moisture content, is determined in the laboratory and provides the target for field compaction. 95 percent is often used as a target compaction threshold to ensure that construction projects are erected on a solid platform. The compactive threshold will be provided by the designing engineer and will be based on the bearing capacity required for the final load to be structurally stable.

We're here to help you find the best solution for your next project. Let's get started. Give me a call at 937-641-9901.

Josh Weser

Mintek Resources

Related Posts

Modernizing Roadbed Construction: Key Updates to Alabama’s Lime Stabilization Specification

The Alabama Department of Transportation (ALDOT) has recently updated its Specification 232 for Lime Stabilized Roadbed, aiming to modernize the standard practices for modifying and stabilizing in-situ soils during roadbed construction.Let's work together. Get Started...

Introducing Construction Quicklime (CQL)

At Mintek, we are committed to addressing the unique challenges faced by the construction industry. Our latest innovation, Construction Quicklime (CQL), is designed to enhance efficiency and ease of use compared to traditional quicklime. CQL stands out due to its...

Understanding Soil Stabilization with Cement and Lime

Creating a strong and stable foundation is essential when constructing buildings, roads, and other infrastructure. However, not all soils are naturally suitable for construction. Some may be too wet, soft, or prone to deformation and settling, which can lead to...