Building Big Starts Below Ground: Soil Strategies for Mega Projects

Mega construction projects come with unique soil challenges that can derail schedules and inflate budgets if not addressed early. Managing soil variability across hundreds of acres while achieving the bearing capacity required for massive structures demands a strategic approach. Lime-based soil stabilization offers a proven solution – delivering significant cost savings compared to remove-and-replace methods while keeping projects on aggressive timelines.

Get back to work with less downtime.

Why Soil Matters More on Mega Projects

The ground beneath your project isn’t just dirt—it’s the foundation for every timeline and budget decision. On smaller sites, a soft spot might cause minor delays. Scale that to 500 acres, and the same issue becomes a major obstacle.

Mega projects don’t have the luxury of working around problematic soil conditions. Every challenge must be solved at scale, making strategic soil treatment from day one essential to success.

What Are the Biggest Soil Challenges in Mega Projects?

Wet and Unstable Soil Conditions

Wet soils create expensive delays on large construction projects. When moisture content exceeds optimal levels, achieving proper compaction becomes extremely difficult, nearly impossible. Site surveys conducted during dry seasons can be misleading, as conditions change dramatically when weather patterns shift.

Temperature Fluctuations

Temperature extremes compound moisture problems significantly. Frozen ground increases costs compared to normal operations, as it requires heavy-duty equipment and can slow excavation progress. The challenge doesn’t end with excavation. Spring thaw converts frozen soil into saturated material that won’t support equipment loads, creating a cycle of weather-related delays. Understanding what to know about cold weather liming helps project teams maintain productivity during challenging winter conditions.

Equipment Issues

Equipment literally can’t operate on oversaturated subgrades without sinking or causing damage to the soil structure being prepared. Contractors face a difficult choice: wait for conditions to improve naturally or find a solution that allows work to continue. For large scale infrastructure projects operating on aggressive schedules with multiple crews and substantial equipment investments staged on site, waiting for ideal weather isn’t viable. Every day of weather delay compounds schedule pressure on subsequent activities.

The financial impact extends beyond daily equipment costs. Labor crews remain on payroll whether productive or idle. Subcontractors scheduled for later phases may need to be rescheduled, potentially at premium rates. Equipment rental costs continue regardless of productivity. These conditions don’t just slow progress—they can shut down earthwork operations entirely, creating significant daily costs in idle equipment and labor.

Soil Variability Across Large Sites

Large-scale projects rarely have uniform soil conditions. Because almost all “desirable” sites have already been developed, contractors often find themselves cutting material from hilltops and using it as fill in adjacent low-lying areas to obtain final grade for the project.

A single site might contain pockets of high-plasticity clay, sandy soil with poor cohesion, and complex transition zones between different soil types. Organic matter content also varies, affecting how soil responds to treatment. Additionally, available sites were often used as “dump pits,” receiving soil from many different locations, further increasing variability. This variability demands flexible treatment strategies that can adapt to changing conditions.

The Expansive Soil Problem

Expansive soils create particular risks at mega-project scale. These clay-rich soils can swell 10% or more when moisture content increases, then shrink dramatically during dry periods. The volume change isn’t uniform across a site, creating differential movement. Across a million-square-foot building footprint, this movement causes cracked foundations, buckled floors, damaged utility lines, and structural integrity issues. Doors and windows that worked during construction suddenly won’t close properly.

Understanding Plasticity Index

The Plasticity Index (PI) of problematic soils often exceeds 30, placing them outside of commonly accepted ranges for construction without significant soil modification. High PI values indicate soil that behaves almost like modeling clay when wet – completely unsuitable for supporting structures or pavement. Soils with a higher PI typically exhibit greater shrink-swell behavior, requiring more intensive chemical stabilization treatments.

Bearing Capacity Requirements

Mega projects impose extraordinary loads on foundation soils. Distribution centers fully loaded with inventory, highways supporting heavy truck traffic, and industrial facilities all demand exceptional bearing capacity.

Settlement Problems

Inadequate bearing capacity creates immediate and long-term problems. Long-term differential settlement happens as different areas settle at different rates, leading to uneven surfaces and structural distress like cracked walls, floors, and drainage systems that flow backward.

Why Natural Soil Often Falls Short

Soil tests frequently reveal that natural conditions don’t provide sufficient support. Factors such as poor bearing capacity, low shear strength, inadequate compaction, and high moisture sensitivity can compromise structural integrity. The choice becomes clear: excavate and replace massive quantities at enormous cost or improve existing soils through stabilization for a fraction of the expense while achieving superior long-term performance.

How Does Soil Stabilization Support Mega Projects?

Keeps Projects Moving on Aggressive Timelines

On mega construction projects, schedule delays create costs far beyond simple daily expenses, but the equation extends far beyond simple daily costs. Schedule delays cascade through multiple trades, compress later activities, and can trigger liquidated damages that dwarf daily equipment costs.

Chemical stabilization with lime-based products changes this dynamic by transforming weather from an obstacle into a manageable variable.

- Accelerated Drying: Quicklime can absorb roughly 1/3 of its weight in water, and the exothermic reaction generates substantial heat in the process. This unique property means treating wet soils effectively even during rainy seasons when traditional methods would require waiting for natural drying. The heat generation creates visible steam rising from treated areas, dramatically accelerating moisture reduction.

- Speed: Construction Quicklime (CQL) offers even faster results with a reduced mellow period of just four hours or less. This means crews can spread, mix, mellow, and compact within a single shift. This time savings compounds into weeks of schedule advantage.

- Year-Round Work: We keep projects moving despite adverse weather by drying saturated soils during wet seasons and using the exothermic hydration reaction to warm soils in cold conditions. This approach extends construction windows and ensures consistent productivity throughout the year.

Eliminates Massive Remove-and-Replace Costs

The economics of soil treatment become increasingly compelling at mega-project scale. Traditional remove-and-replace approaches rack up costs for excavation, hundreds of truck hauls, rising disposal fees, and importing select fill. Beyond safety and environmental impacts, this surge in heavy truck traffic overwhelms local roads, often designed for light use, accelerating failure and triggering expensive taxpayer-funded repairs and upgrades.

Soil stabilization significantly reduces these costs. Instead of treating existing soil as waste, lime-based stabilization transforms it into suitable construction material, meeting or exceeding specifications for strength and stability. For large-scale projects, these savings can fund additional phases of construction.

Improves Engineering Properties

Lime stabilization fundamentally transforms soil engineering properties, directly addressing the core challenges of variability and instability:

- Immediate Benefits (Soil Modification):

- Reduces soil plasticity by making high-plasticity soils stable and workable.

- Reduces, if not eliminates shrink-swell potential (solving the expansive soil problem).

- It improves workability and lowers moisture sensitivity.

- Helps with compaction.

- Long-Term Strength Gains (Pozzolanic Reaction):

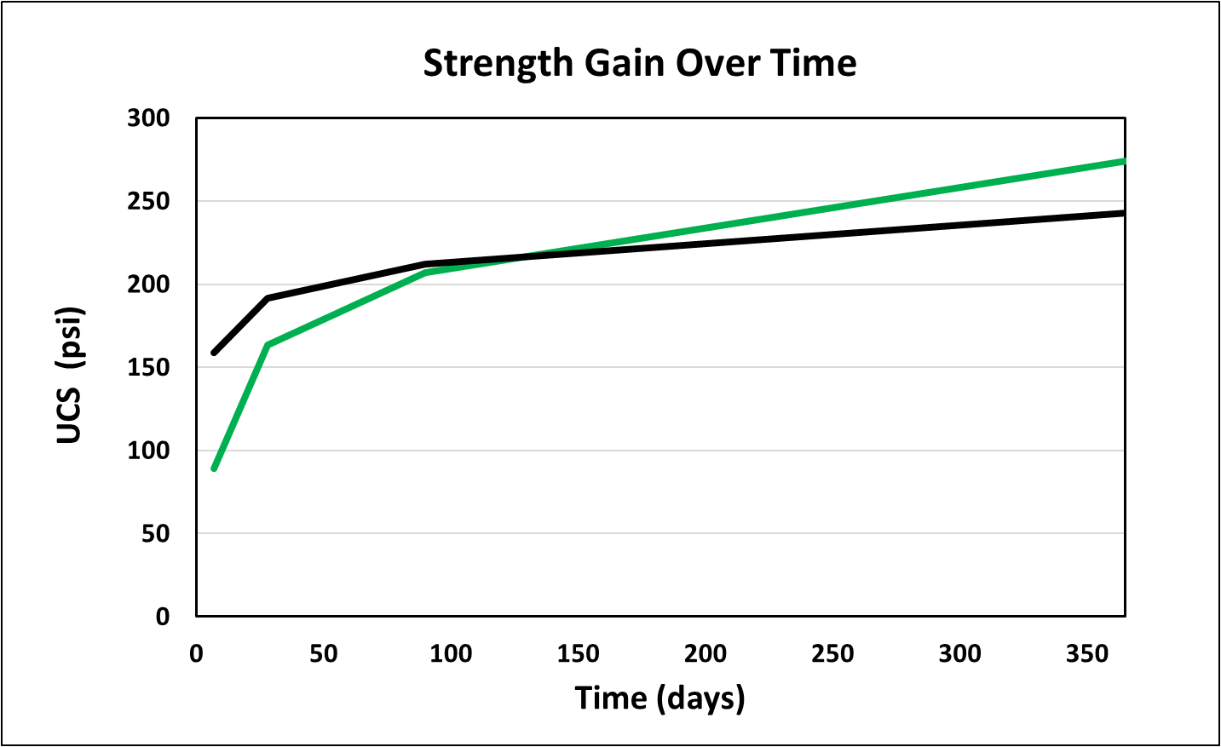

- Unconfined Compressive Strength (UCS) improves from very low levels to well above typical thresholds – commonly exceeding 125 psi and, in some cases, reaching several hundred psi – with continued strength gains over time.

- Pozzolanic reactions continue for months, often doubling initial strength gains.

- Creates stabilized soil capable of supporting heavy loads and meeting the high bearing capacity requirements.

- Construction Advantages: Better equipment support, improved grade holding, and enhanced erosion control. Lime stabilization allows more forgiving timing for compaction compared to alternatives, reducing risk if sequencing changes occur.

Solves Temporary Infrastructure Needs

Mega projects require extensive temporary infrastructure (haul roads, staging areas, crane pads). Lime-based products provide key benefits for temporary needs:

- Transforms muddy routes into all-weather haul roads

- Forms bound layers maintaining integrity under repeated loading

- Provides stable support in soft subgrade conditions

- Provides erosion control during heavy rain

- Often becomes part of permanent construction

What Goes Into Material Storage and Logistics for Large-Scale Projects?

On-Site Storage Solutions

Material availability makes or breaks mega-project schedules. Running out of stabilization materials means idling equipment and workers. Strategic storage ensures continuous operations. Portable storage PIGS offer major advantages:

- 100-120 ton capacity per unit

- Treats approximately 40,000 square yards per PIG

- Multiple units positioned strategically across sites

- Sealed environment protects materials from moisture

- Pneumatic discharge directly to spreader trucks

- Eliminates double-handling inefficiencies

Reliable Carrier Networks for Material Sourcing

Reliable material delivery requires robust logistics. Finding reliable suppliers who understand mega-project pressures prevents costly delays. Our dispatch team works hard and genuinely cares about getting materials where they need to be, when they need to be there.

Essential logistics features:

- Multiple supply sources for redundancy

- Established carrier relationships

- Dedicated delivery windows

- Designated truck routes minimizing disruption

- Driver familiarity with site safety protocols

- Backup plans for unexpected demand

For construction projects requiring 10-20 daily truckloads during peak periods, this reliability proves critical.

Why Does Early-Stage Soil Treatment Prevent Delays and Cost Overruns?

Comprehensive Testing Determines Treatment Requirements

Early soil investigation prevents expensive surprises. Comprehensive soil tests during design phases reveal the true extent of challenges, allowing accurate budgeting and scheduling.

Testing for mega projects includes:

- Moisture-density relationships (of untreated soil as well as after chemical treatment)

- Unconfined compressive strength analysis

- California Bearing Ratio testing

- Complete Atterberg limits determination

- Swell tests for expansive soils

Soil tests also evaluate organic matter content, which can interfere with lime reactions and require adjusted treatment rates. This data forms the foundation for addressing specific site challenges.

Early Treatment Maximizes Stabilization Gains

Early treatment implementation allows stabilization benefits to fully develop before heavy construction begins. Lime-treated soils don’t just stabilize immediately – they keep improving long after application. As time passes, the treatment continues to build strength and durability, creating a solid foundation for construction. Starting early means these benefits have time to fully develop, reducing risks and ensuring long-term performance.

Treating soils weeks or months before building construction achieves:

- Higher final strengths

- Better long-term performance

- Identification of areas needing additional treatment

- Prevention of critical path delays

About Mintek Resources

For over 30 years, Mintek Resources has specialized in lime-based soil stabilization solutions for construction projects of all sizes. Our comprehensive approach combines proven products like Calciment® LKD, quicklime, and Construction Quicklime (CQL) with technical expertise and nationwide distribution serving 34+ states.

From initial soil testing to on-site support, our team helps construction professionals tackle challenging soil conditions efficiently. Contact Mintek Resources at 937-519-3068 or visit mintekresources.com to discuss your project needs.

FAQs

How do you stabilize weak or expansive soil for construction?

The most effective method for stabilizing weak or expansive soils, particularly soils high in clay content, is lime-based chemical stabilization. This process reduces plasticity, eliminates shrink-swell behavior, and increases soil strength through pozzolanic reactions. It creates a durable foundation capable of supporting heavy loads and is more cost-effective than removing and replacing unsuitable soil.

Can you add new soil over existing unstable soil?

Placing new soil over an unstable subgrade without proper stabilization can lead to settlement and structural failure. Always stabilize the existing soil or remove it before adding new material to ensure long-term performance.

How do you protect topsoil and site soil during construction?

To protect soil during construction:

- Stockpile topsoil in designated areas away from traffic.

- Cover stockpiles with erosion control measures.

- Clearly mark locations to prevent contamination.

- Limit vehicle access to haul roads and stabilize temporary work areas with lime-based products.

We're here to help you find the best solution for your next project. Let's get started. Give me a call at 937-641-9901.

Krystan Minor

Mintek Resources

Related Posts

5 Keys to Successful Soil Stabilization

Creating a solid foundation for construction projects depends on proper soil stabilization. While every job site presents unique challenges, successful stabilization is consistently achieved when teams follow proven best practices backed by testing, planning, and...

Cold Weather Liming for Construction Sites: Everything That You Need to Know

Winter construction doesn't have to mean costly shutdowns. Cold weather liming for construction sites leverages the exothermic reaction of lime-based products to dry, modify, and stabilize soils even in freezing conditions. This comprehensive guide covers the science...

Tariffs Disrupt Construction: Lime Keeps Projects Moving

Tariffs are reshaping the construction landscape. From cement and steel to aluminum and other essential materials, shifting trade policies are creating ripple effects across the industry. Even when prices hold steady, the uncertainty around future costs and sourcing...