How to Stabilize Clay Soil

What is Soil Stabilization?

Soil treatment is often considered when a construction site contains problematic soils. These soils can be overly wet and unable to be compacted properly and require drying; they may be sticky, prone to rutting and generally difficult to work with, requiring modification; or they may be lacking the necessary adequate strength and shrink-swell resistance to provide long-term stability for the road or structure being placed above the treated soil, requiring stabilization. When strength is needed, a soil stabilization process is often desired.

Generally, soil stabilization requires a higher application rate and more thorough processing than when simply drying or modifying a soil.

The basic steps include:

- Scarifying or partially pulverizing soil

- Spreading the chemical agent

- Adding water and mixing

- Compacting to maximum practical density

- Curing prior to placing the next layer or wearing course

However, we are getting ahead of ourselves. Typically, well before any soil stabilization equipment, such as a soil reclaimer, is used on the jobsite, the soil types must be identified, stabilization agent(s) determined, and dosage(s) verified in the lab.

Soil Types and Proper Identification

The success of your soil stabilization project begins with knowing the type of soil that requires treatment. Understanding its engineering properties will help guide you to choosing the best soil stabilization agent. Two soil properties are specifically useful in the selection: particle size distribution and plasticity. Any soil being considered for stabilization should have their properties identified through proper laboratory testing methods. This includes ASTM C136 – Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates to determine the particle distribution of the soil and ASTM D4318 – Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils to determine the soil’s plasticity.

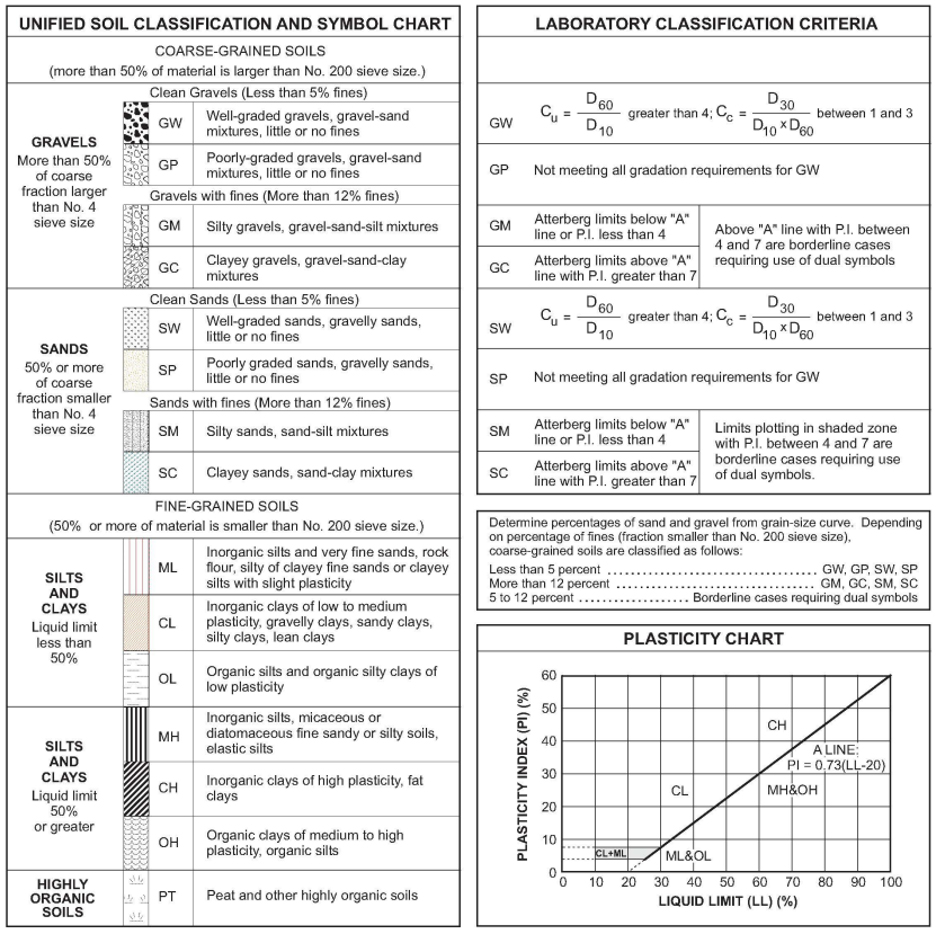

With this information, a soil can now be classified. The Unified Soil Classification System (USCS) is one of several methods commonly used for classifying a soil based on its particle size distribution and plasticity, and standardizes the terms for gravel, sands, silts, and clays and further subclassifies based on their proportion and plasticity (Figure 1).

FIGURE 1 – Unified Soil Classification Chart

This is particularly important for the more problematic soil types, which are silt and clay soils. Clay soils (also known as expansive soils) can be highly plastic and prone to swelling. Clay soils are often difficult to work with because they tend to become malleable, sticky, and soft when wetted. Silt soils can become “quick” when saturated where they can assume the character of a viscous fluid and flow. They are difficult to compact and susceptible to frost heave in colder climates. Fortunately, even these problematic soils can be transformed into a desirable soil with the right soil stabilizing agent.

Choosing the Right Soil Stabilizer

A soil’s classification (e.g., clay soil, sandy soil, etc.) should guide the decision as to which soil stabilization agent is most suited to provide the desired results. For a stabilized subgrade, the treated soil (e.g., lime-soil or soil cement) should develop the strength needed for its intended purpose (pavement support, embankment strength, rutting resistance, etc.) and be able to endure the environmental conditions (freeze-thaw, extended soaking, etc.) that it will experience over its desired service life.

While many soil stabilization agents have been used, the most common are quicklime, lime kiln dust (LKD), and Portland cement. Fly ash was once more popular, but with the reduction of coal fired powerplants in the United States, the availability of fly ash (both Class C Fly Ash and Class F Fly Ash) has dramatically diminished in recent years, with most acquired by the concrete industry for their use. Chlorides, such as sodium chloride and calcium chloride, have also been successfully used to provide strength and dust control for acidic soils, but have proven less reliable as a stabilization agent. Cement kiln dust (CKD) can have high concentrations of expansive minerals and has been banned from use by several agencies. Therefore, the focus here will be distinguishing when to use lime-based products (lime, LKD, Calciment®) and Portland cement.

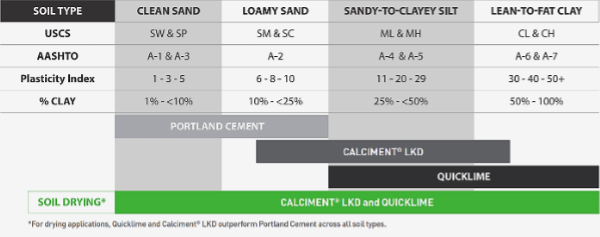

For sandy and sandy-silty soils with little to no plasticity, Portland cement is often the best choice due to its ability to cement the coarser sized soil particles to one another. However, as a soil becomes more clay mineral rich and plastic, Portland cement effectiveness begins to diminish. This is when quicklime (and all lime-based products, such as LKD and Calciment®) has proven to be the more effective stabilizing agent. This is because a silty or clay soil that has even modest plasticity (plastic index >10 per ASTM D4318) will inherently have a suitable amount of silica and alumina compounds provided by the clay present in the soil to cause a pozzolanic reaction with the lime and form cementitious bonds.

Several owner-agencies (State DOT’s, U.S. Armed Forces, etc.) as well as the lime industry (National Lime Association) have developed general guidelines for determining a soil’s suitability for lime/LKD stabilization. A widely used criteria used for determining whether to use lime/LKD or Portland cement is as follows:

“Generally, a soil with at least 25% passing a 75-micron screen and having a plastic index (PI) >10 are strong candidates for lime stabilization.”

We here at Mintek Resources have developed a reference tool that further aids in this decision process (Figure 2).

Figure 2 – Chemical Stabilization Guide

Finally, when intentionally using a chemical binder as a soil stabilization agent – rather than simply soil drying or soil modification – understanding the long-term properties of the stabilized soil is critical. Verifying that the stabilized soil will meet the long-term goals for the life of the project is an important part of the engineering process to validate the effectiveness and determine the proper dosage rate. (Click here for a complete technical brief on “Mixture Design and Testing Procedures for Lime Stabilized Soil”)

Soil Stabilization Methods

The two most common methods for stabilizing soils are in-situ mixing and treat-then-place mixing. With in-situ stabilization, problematic silty and clay soils can be quickly treated in-place by simply spreading the stabilization agent (e.g., lime, LKD, or cement) over the soil, ensuring proper moisture, and then mixing the bonder into the soil. This can be added to the soil as dry powder or as slurry. Ideally, the binder would be placed with a spreader truck and then mixed using a soil reclaimer (see Figure 3) to produce a thoroughly blended final product. This method is most effective when the treatment depth is less than or equal to 16-inches. With this method, site soils are transformed into an engineered material, eliminating the need to remove and replace the soil.

Figure 3 – Soil Spreader & Soil Reclaimer

When the depth of treatment is greater than 16 inches, the soil being treated is being used to build an embankment, or a soil reclaimer is not being used, the treat-then-place method is often used. For example, a soil may be chemically treated prior to placement. For this method, the problematic soils are typically treated by working the soil stabilization agent into a predetermined amount of soil to achieve the desired dosage rate. This mixing is often done with a backhoe whose operator carefully works the binding agent into the soil until thoroughly incorporated. Today, there are even mixing attachments that can be used with the backhoe to speed up the process (Figure 4).

Figure 4 – Backhoe with mixing attachment treating soil prior to placement

When using this method, lime stabilized soil can be stockpiled and sit loose for hours and potentially several days with minimum impact if not exposed to heavy precipitation. However, with Portland cement, the treated soil must be placed and compacted within four hours due to the fast cure time of cement.

For a more in-depth look at all the possible mixing techniques, please refer to our “Soil Stabilization Methods and Materials” blog here.

Benefits and Uses of Lime Treated Soil

Wet, weak, fine-grained soil can prove to be a major challenge at many construction sites. Muddy site conditions make for difficult working conditions. Access is difficult for construction vehicles. It’s difficult to reach the soil moisture and compaction requirements established by the project civil or geotechnical engineer. Wet, poorly compacted soil makes for poor pavement support and embankment/fill. At a construction site, lost time means lost money. While most soils can benefit from the use of a stabilizing agent, when dealing with problematic soil types, lime and LKD simply offer the most benefits, which include:

- Substantial increases in soil properties, including unconfined compressive strength, shear strength, CBR, resilient modulus and plasticity reduction.

- Continued strength gain with time.

- Long-term durability (wet-dry, freeze-thaw) of strength gains over decades of service.

- Reduction of volume changes in expansive clay soil.

- For road construction, a reduction in pavement thickness due to the higher strength of lime stabilized subgrade soil and improved load bearing capacity.

Save Time — Save Money — Improve Subgrades

We're here to help you find the best solution for your next project. Let's get started. Give me a call at 937-641-9901.

Josh Weser

Mintek Resources

Related Posts

Building Big Starts Below Ground: Soil Strategies for Mega Projects

Mega construction projects come with unique soil challenges that can derail schedules and inflate budgets if not addressed early. Managing soil variability across hundreds of acres while achieving the bearing capacity required for massive structures demands a...

Cold Weather Liming for Construction Sites: Everything That You Need to Know

Winter construction doesn't have to mean costly shutdowns. Cold weather liming for construction sites leverages the exothermic reaction of lime-based products to dry, modify, and stabilize soils even in freezing conditions. This comprehensive guide covers the science...

Tariffs Disrupt Construction: Lime Keeps Projects Moving

Tariffs are reshaping the construction landscape. From cement and steel to aluminum and other essential materials, shifting trade policies are creating ripple effects across the industry. Even when prices hold steady, the uncertainty around future costs and sourcing...