Soil Drying Agents

When Should I Use a Drying Agent?

Time equals money and job site delays can result in higher production costs and lost opportunities. Contractors and project owners are required to stay on schedule and also on budget, while achieving the geotechnical specifications for sub-base soil strength and compaction, regardless of ambient weather conditions. During rainy seasons, or for soils with high moisture, achieving optimum moisture content and compaction can prove difficult, especially during long periods of cold, wet, snowy weather. The use of lime-based reagents will accelerate the drying of soils regardless of ambient conditions.

The impact of water in the process of soil compaction cannot be overstated. To ensure the long-term integrity of the pavement structure, the sub-base soils must reach certain criteria for strength and compaction. Soils with too much moisture contain voids that fill with water and compress when weight is applied creating instability and increased risk of shrink / swell. Over saturated soils are impossible to compact and achieve the strength required for most job site specifications.

Get back to work with less downtime.

Drying reagents, such as Quicklime, Lime Kiln Dust (LKD), and Calciment<sup>®</sup> can be used to adjust the moisture and improve the workability of problematic soils. When encountering wet site conditions, lime-based reagents accelerate drying with heat generated through exothermic hydration reactions. Additional benefits include reduced plasticity when cations (Ca++ & Mg++) react with clay particles to chemically modify soil. By modifying the properties of clay-based soils, the compaction and stability of the soil are improved and shrink / swell potential is minimized. Lime-based reagents also provide enhanced bearing capacity and a long-lasting sub-base structure via short and long-term strength gains thanks to cementitious properties. What’s more, chemical drying with lime-based products provide significant cost savings vs. alternative reagents or remove and replace methods.

How to Use a Soil Drying Agent

Lime-based drying reagents, such as Calciment<sup>®</sup> LKD, also known as Lime Kiln Dust, and Quicklime, will help quickly dewater wet soils to reach optimum moisture content (OMC). The reagent is applied at a pre-determined dose rate (typically 2%- 5% depending on soil conditions), mixed into the soil and hydrated. Hydration is required to create the exothermic chemical reaction that generates heat. The substantial heat generated by our lime-based solutions drives the reaction of our products even in cold soil, drying it to your desired moisture and keeping your job on schedule. In extreme cases, our lime-based products have been used to thaw frozen soils.

In addition to heating and drying, the unique chemistry of lime-based products will also stabilize clay soils and dramatically improve their properties. . Improvements include reduced plasticity, increased short and long term strength, enhanced workability, decreased swell potential and added protection against loss of compaction from future wet-dry and freeze-thaw cycles.

Optimum Moisture Content: Drying with Mintek’s Drying Reagents

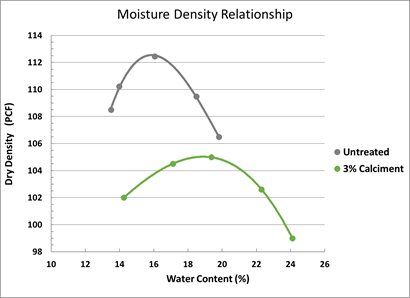

The determination of maximum dry density and optimum moisture content of soil is based on the compaction levels of the soil. A geotechnical testing laboratory can help determine the optimum moisture content using test methods including a Standard Proctor Compaction Test and/or a Modified Proctor Compaction Test. Lime-based reagents will decrease the moisture in the soil and increase the optimum moisture content for better strength and compaction. A proctor should be performed on treated soil in the field to verify on-site compaction.

Typical Application Process

Quicklime or Calciment is transported to the job site in a Pneumatic Tanker.

Then, the lime-based reagent is transferred to a Spreader Truck.

The Spreader Truck then spreads product over problematic soil.

Calciment LKD or Quicklime, water and soil are mixed using a Water Truck and Reclaimer.

The material and soil are then graded to a profile and cross slope.

The surface is ready for a final smooth roll and seal before building or paving.

How can Mintek Help?

Ensure you are using right product for your specific project by contacting Mintek’s technical support team to understand your specific job site requirements. Our full service geotechnical laboratory can perform soil testing to help determine the optimum moisture content to meet your strength and compaction requirements. Our technical experts are also available to help troubleshoot field issues, consult on dose rates and ensure you are using the right solution based on your job site requirements. Mintek’s supply chain experts will then make it effortless to get the product you need, when you need it. We have multiple distribution points for ease of transport and continuity of supply to keep projects moving.

We're here to help you find the best solution for your next project. Let's get started. Give me a call at 937-641-9901.

Josh Weser

Mintek Resources

Related Posts

Soil Compaction: Methods, Meaning, and Effects

What is Soil Compaction? Soil compaction is the practice of applying mechanical compactive effort to densify a soil by reducing the void space between soil particles. Compaction occurs when particles are pressed together to reduce the space between them. Highly...

Sludge Drying Overview

What are Some Common Difficulties Associated with Sludges? The term “sludge” generally refers to the residuals that remain after industrial and commercial processes, such as the treatment of biosolids, drinking water, and wastewater. In addition to potential...

Soil Compaction Test for Construction

What Is Soil Compaction Testing? Soil compaction testing for construction determines if adequate mechanic stress was applied at the appropriate water content to achieve maximum density. Assuming fixed compaction effort, the only variable the contractor can control is...