Soil Compaction Test for Construction

What Is Soil Compaction Testing?

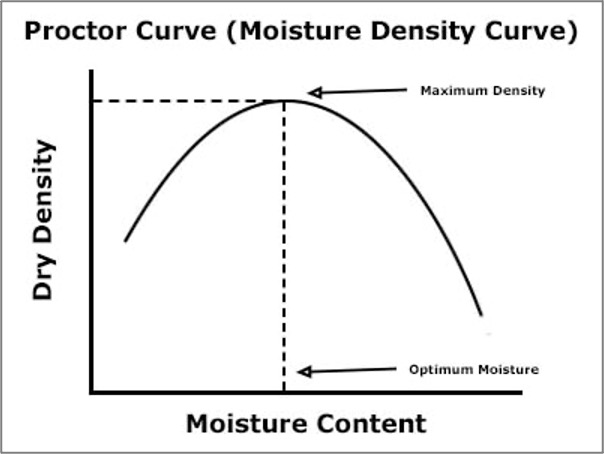

Soil compaction testing for construction determines if adequate mechanic stress was applied at the appropriate water content to achieve maximum density. Assuming fixed compaction effort, the only variable the contractor can control is the moisture content of the soil. The goal is to ensure the moisture content is adjusted to allow the soil to compact so that it reaches its maximum dry density.

To visualize this, think about taking a walk across a beach toward the ocean. On a hot, sunny day the sand is very dry and your feet sink and slide in this loosely compacted sand. As you near the ocean, where the tides have provided moisture to the sand, it firms up and you no longer sink into the more stable sand. This is the perfect spot to build that sandcastle! Here, the sand has acquired its optimum moisture content (OMC), providing the perfect amount of lubrication to achieve maximum dry density (MDD). However, as you continue your journey toward the ocean, you again begin to feel your feet sink back down into the sand. The sand has become less stable because there is now too much water within the voids of the sand particles.

Back on a construction site, measurements are taken to determine actual values using a number of methods, from the simplistic sand cone test to utilizing a nuclear densometer (nuke) gauge for testing. These tests provide the parameters needed to develop a Proctor curve, which is needed to determine the OMC for a given soil. Proctor curves are typically determined from preliminary laboratory testing and then verified during construction to ensure that adequate densities are being achieved.

Let’s work together.

Standard 5-Point Proctor

The standard Proctor test (ASTM D698 / AASHTO T 99) is sometimes referred to as a “5-point” because it requires five samples with differing moisture content and correlating density to develop a curve. At the peak of that curve lies the MDD and OMC, which identifies the optimum moisture required for proper compaction. This point is typically different for each soil and soil modification through chemical treatment further shifts the curve. Therefore, it is critical to develop the Proctor curves on soils after the addition of stabilizing materials, like lime, to ensure that you are working off the correct curve. Failure to do so often results in the soil being compacted dry of optimum resulting in inadequate compaction and failed proof-roll testing.

Modified (5-Point) Proctor

It is worth noting that there is another Proctor method, the modified Proctor. The modified Proctor test, which applies approximately four times the compactive effort compared to the standard Proctor test, was developed around WWII and introduced in 1958 as ASTM D1557 and AASHTO T 180 to better represent higher load applications where soils would compact to higher densities at lower moisture contents. If chemically stabilizing the soil, it is important to note that a low moisture content may result in an insufficient amount of water being available within the soil to fully react and provide the desired engineering property improvements. Calcium-based reagents, including lime and Portland cement, must fully hydrate with water to be effective. Generally, the higher compaction is not necessary for most projects like building pads, parking lots or roads, and the standard Proctor test will yield the optimum results. However, if chemical stabilization is required on soils utilizing a modified Proctor, it is best practice to compact 1% to 3% above optimum to provide additional water for the hydration process.

One-Point Proctor

Many state DOTs allow what is called a one-point proctor (AASHTO T 272) to quickly determine if conditions on the site match those tested in the lab. A one-point uses a family of 5-point Proctor curves previously determined from local soils. It is useful in that only one test specimen needs to be molded and analyzed, not five. This is faster and less expensive than sending samples back to a lab for analysis but may not be as accurate as a 5-point. The lack of accuracy is particularly true if the site soils are going to be treated with a stabilizing chemical as the curves would likely not have been developed using the matching stabilizing agent. It is best practice to verify the OMC with all soils that are going to be chemically treated with a 5-point Proctor made from a soil treated with the stabilizing agent that is to be used as the predetermined dosage.

Other Testing Methods

Now that you are confident with your laboratory derived OMC and MDD, several test methods may be used to determine if compaction goals are met in the field. These include the sand cone test (ASTM D1556 / AASHTO T 191), the rubber balloon test (ASTM D2167 / AASHTO T 205 (withdrawn) and nuclear density testing (ASTM D6938 / AASHTO T 310). The first two methods are similar in that a small area is excavated and the void is filled with sand or a pressurized water balloon. The volume of sand or water in the balloon that is necessary to fill the hole can then be determined. Both tests require the unit weight and the water content of excavated soil for calculations.

Nuclear density gauges use controlled, transmitted radiation to measure the density of soil. There are two ways that a nuke gauge can work: direct transmission or backscatter. Direct transmission works by inserting a radioactive probe into the soil via a pilot hole before the transmitted radiation is measured over a short time. Backscatter is less reliable but faster because the probe is not extended into the soils, so no pilot hole is necessary. Since the nuclear density gauges contain radiation, they are closely monitored and regulated.

What Construction Professionals Should Know

- Proctor Testing is Essential: Accurate field compaction targets originate back in the lab with a 5-point Proctor. The optimum moisture content (OMC) tells those in the field the exact water content needed to hit peak compaction. Testing also helps determine the minimum required density so crews know exactly how much compactive effort is needed and how field conditions compare to controlled lab conditions.

- Develop an Accurate Proctor Curve: A chemically treated soil will have different moisture and density compaction targets than an untreated soil. Usually, a treated soil will have a higher OMC compared to untreated. Be sure that the target curve was derived from chemically treated soils if the site soils are also being chemically treated.

- Risk of 1-Point Proctor: A one-point Proctor is a fast way to determine whether conditions on the construction site match those tested in the lab. However, it’s crucial that the family of curves are derived from local soils. Also, when chemically treating soils, it is best practice to verify the OMC with a 5-point Proctor made from a soil treated with the stabilizing.

- Field Verification Options: Using a nuke gauge is popular on large sites due to how fast results are produced. However, other methods like the sand cone and rubber balloon methods are viable options as well.

We're here to help you find the best solution for your next project. Let's get started. Give me a call at 937-641-9901.

Josh Weser

Mintek Resources

Related Posts

Building Big Starts Below Ground: Soil Strategies for Mega Projects

Mega construction projects come with unique soil challenges that can derail schedules and inflate budgets if not addressed early. Managing soil variability across hundreds of acres while achieving the bearing capacity required for massive structures demands a...

Cold Weather Liming for Construction Sites: Everything That You Need to Know

Winter construction doesn't have to mean costly shutdowns. Cold weather liming for construction sites leverages the exothermic reaction of lime-based products to dry, modify, and stabilize soils even in freezing conditions. This comprehensive guide covers the science...

Tariffs Disrupt Construction: Lime Keeps Projects Moving

Tariffs are reshaping the construction landscape. From cement and steel to aluminum and other essential materials, shifting trade policies are creating ripple effects across the industry. Even when prices hold steady, the uncertainty around future costs and sourcing...