Anti-Stripping Agent for Asphalt – Application, Process, and Effect

What are the Different Types of Hot Mix Asphalt Plants?

There are two basic configurations for plants used in the production of Hot Mix Asphalt (HMA), continuous or batch plants. Both configurations use two main ingredients, aggregate and asphalt binder. A Hot Mix Asphalt plant consists of liquid asphalt tanks, conveyor belts, heating and mixing chambers, and silos containing the finished product. At a high level, aggregate is dried then further heated before being coated with asphalt to produce asphalt concrete. Reclaimed asphalt pavement, or RAP, can be used to minimize the need for virgin ingredients by recycling previously used materials.

Get back to work with less downtime.

Three Types of Hot Mix Asphalt

Dense Graded Mixes

- Dense graded mixes are made up of well-graded aggregates and asphalt binder. Well-graded meaning they have an even distribution of particle sizes that ranges from coarse to fine. This even distribution allows the overall mix to pack together into a dense layer that is relatively impermeable. These designs can be further categorized into coarse-graded and fine-graded mixes. Fine-graded mixes have lower permeability and smoother texture. However, they must be placed in thinner lifts giving good durability to low volume roads. Coarse-graded mixes allow for thicker lifts with an increased texture.

Stone Matrix Asphalt (SMA)

- Stone matrix asphalt is gap graded and has increased durability and resists permanent deformation associated with rutting. As its name implies, the medium that gives this mix strength is stone on stone friction. This strength allows its use on high volume roads such as interstates and highways, as well as, on ports and distributions centers. Stone Matrix Asphalt is a specialized mix that often comes with a premium associated with high quality materials.

Open-Graded Mixes

- Open-graded mixes are used on the pavement surface to allow water to permeate through them. This gives a safety factor for motorists in wet conditions. Gradation, compaction, and void determination are important components of open-graded mixes.

Asphalt Additives

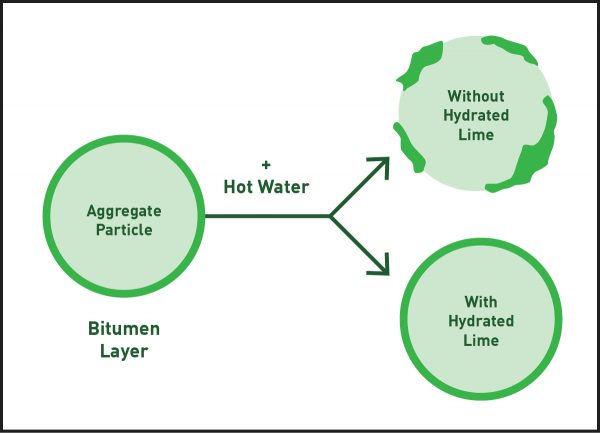

One of the leading causes of deterioration in asphalt is moisture-induced stripping of the asphalt binder from the aggregate. There are two broad categories for anti-stripping agents for asphalt, hydrated lime or liquid anti-strip. Hydrated lime is the superior additive when it comes to minimizing the stripping potential. When added to the asphalt mix, hydrated lime increases the rate and strength of the binding between the aggregate and binder. Liquid anti-strip can also increase the adhering forces between the aggregate and the asphalt. There are many aspects to consider when choosing an anti-strip agent, but acceptance and proven history are some of the key criteria.

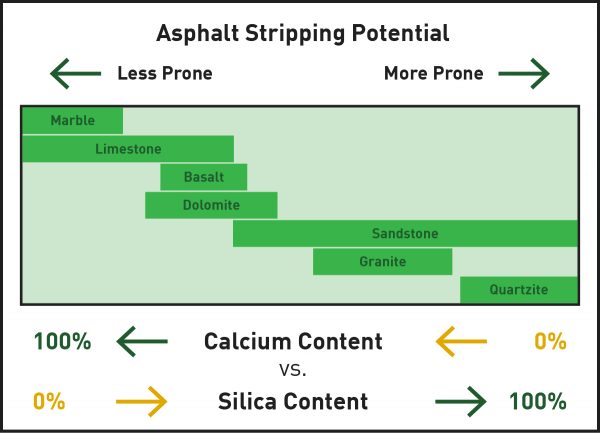

The chemistry of the aggregate is a driving factor in the cause of antistripping; more specifically, the calcium and silica content of the aggregate. Some types of aggregates have a higher stripping potential than others. The risk of moisture-induced stripping is reduced when limestone and marble aggregates are used, and therefore hydrated lime is typically not needed. Granite and quartz rich aggregates are more susceptible to stripping, and anti-strip agents such as hydrated lime is needed, or the asphalt may prematurely fail.

Finally, a large factor that is to be considered is the cost and ease of application. Hydrated lime is the economical option, but liquid anti-strip can be easier for contractors to use.

Hot Mix Asphalt vs. Warm Mix Asphalt

Hot Mix Asphalt is still the dominant process for asphalt. However, the acceptance of Warm Mix Asphalt has seen an increase in the last 15 years for environmental impacts.

| Hot Mix Asphalt (HMA) | Warm Mix Asphalt (WMA) |

| The traditional asphalt mix used for decades. It is made up of stone and sand that is bound together by asphalt cement. For the asphalt cement to bind to aggregate, the stone is heated between 250-375° F. | Similar to Hot Mix Asphalt, but the mixture is not heated to as high of a temperature. It can be mixed and placed at up to 40° F cooler than traditional Hot Mix Asphalt. |

Asphalt Chemistry

Asphalt composition is intricate and differs greatly among different sources of crude oil. Crude oil is the remains of organisms that roamed the earth millions of years ago, were buried in sediments, consumed by microorganisms and transformed into crude oil. The chemistry of asphalt is a complex combination of different organic molecules, mostly carbon and hydrogen. Other atoms combine to form substances known as asphaltenes that are suspended in a mixture of oils and resins known as maltenes. Variations in chemistry and production process affect the final composition and physical characteristics.

We're here to help you find the best solution for your next project. Let's get started. Give me a call at 937-641-9901.

Josh Weser

Mintek Resources

Related Posts

What is Hydrated Lime?

Hydrated lime, sometimes referred to as “slaked lime” or more likely just “hydrate”, is a versatile chemical with many uses across numerous industries and applications. Technically, hydrated lime is calcium hydroxide, Ca(OH)2, a derivative of quicklime – another...