Projects

City of Xenia, OH

Market

Application

Dose Rate

A number of roads in the City of Xenia, Ohio had far surpassed their service life and required an economical solution to rehabilitate their streets. Calciment® was chosen for this FDR project because of its past successes and a 45% cost savings vs. traditional remove & replace methods.

Project Overview

- Xenia, OH needed a quick and cost-effective solution for rehabbing a number of roads that had surpassed service life

- Calciment® LKD was chosen due to past success with FDR jobs and resulted in a 45% cost savings over remove and replace

- The existing base was recycled, Calciment® LKD was applied, and new asphalt was laid resulting in long-lasting roads

Background

In 2006, a number of streets within the City of Xenia, Ohio reached the end of their service lives. While the asphalt pavements performed well for over three decades, Ohio’s fluctuating weather conditions and heavy traffic patterns led to major distress on some roads. These pavements required major rehabilitation or complete reconstruction.

The Challenge

Complete pavement reconstruction was a costly option, which would put strain on Xenia’s limited budget for public works improvement. However, less costly repair techniques, including thin asphalt overlays, were not suitable due to the severity of the road damage. Thick structural asphalt overlays were also not suitable unless existing curbs and gutters were replaced and considerable work done to match or adjust existing residential driveways, roadway drainage structures and adjoining intersections.

The Solution

The City of Xenia was looking for a quick, cost efficient method to completely replace the failed flexible pavement roadways. Two options appeared viable:

- Remove and replace the existing flexible pavement, or

- Reclaim the existing pavement materials in-place using fulldepth reclamation (FDR). Full depth reclamation also offered the opportunity to incorporate Calciment® LKD to add strength and long life to the recycled flexible pavement.

Due to the success of past FDR jobs utilizing Calciment® LKD, the City of Xenia quickly determined this process would be less costly, quicker, and would provide the long-lasting quality results the city demanded. Plans and bid documents were prepared and the project was let for bid. Ray Hensley Construction, Inc. of Springfield, Ohio, an experienced company specializing in FDR and soil stabilization, was selected.

Results

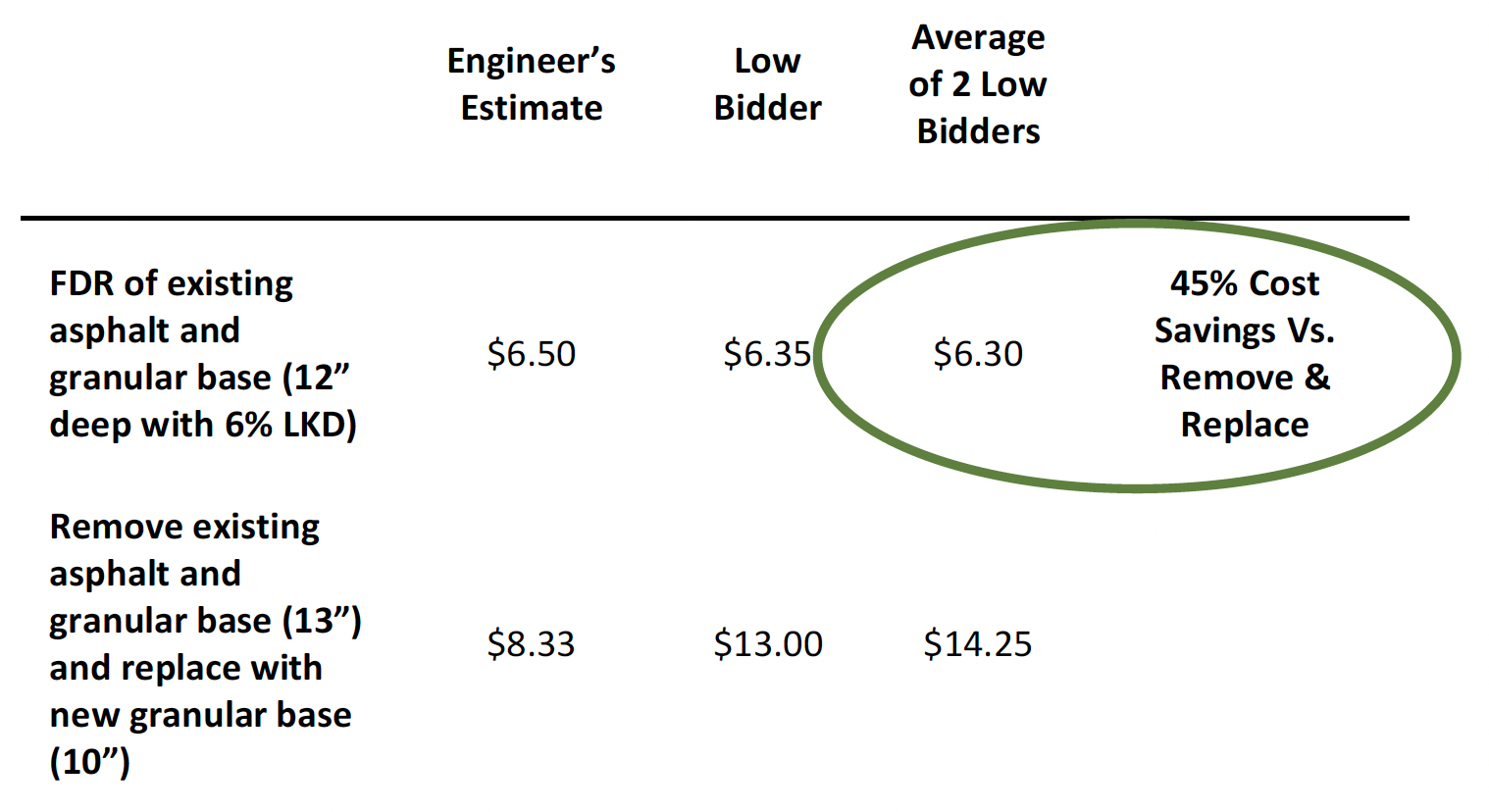

CA quick review of project bid tabulations, summarized in Figure 1, shows the value that FDR with Calciment® LKD brought to the City of Xenia.

These projects were bid separately in Spring 2006, but the size and scope of the projects are very similar, allowing for a meaningful cost comparison. It is important to note that the cost figures shown in Figure 1 are for base construction only and do not include the cost of the asphalt surface course. In both cases, a 3” thick asphalt overlay was placed on the reconstructed base course.

In many FDR projects, the existing asphalt pavement is recycled with the underlying base material. In this case, however, the existing asphalt mat was removed prior to recycling. By removing the old 3” thick layer of asphalt and then recycling the existing base with Calciment® LKD, a new 3” layer of asphalt could be placed on the newly recycled base – allowing the new pavement to meet existing curbs and gutters, residential driveways, manholes and enjoining intersections.

In addition to being more cost effective, the speed of construction and high quality base material were also key successes of the project. “Public inconvenience is one of our major concerns during roadway repairs. When we have to completely reconstruct a residential street, we know that the residents and driving public will be effected. But we want to keep road closures and downtime to a minimum. With FDR, we have far fewer construction vehicles in our residential neighborhoods. No trucks are needed for hauling out the old pavement and bringing in the new aggregate base. The recycling process is very quick and residents can drive on the recycled base until the new asphalt surface course is placed.” Stated Jim Jones, Xenia City Engineer

Figure 1: Cost of base reclamation with Calciment or removal and replacement (per square yard)

Lasting Success

FDR utilizing Calciment® LKD saved the city thousands of dollars and provided the lasting results they desired. In addition, FDR utilizing Calciment® LKD was four times faster than a complete reconstruct. Years after the project was finished the roads are still providing optimal performance!

City of Xenia

Case Study

“When compared to pavement removal and replacement, full-depth reclamation with Calciment is quicker, less costly and gives us a better road.”