Projects

ODOT US Route 24 in Cecil, OH

Market

Application

Dose Rate

An embankment in northwestern Ohio started to slip due to extensive rainfall, requiring ODOT to quickly find a solution. Based on test results, ODOT decided the best solution was to chemically stabilize the weak, in-situ soil of the embankment by using Calciment® LKD.

Project Overview

- Embankments in northwestern Ohio started to fail after a very wet 2019

- Mintek worked closely with ODOT and the contractor to evaluate and find a solution

- The UCS of the soil was improved from 15 psi to 160 psi and the project was completed on time.

Background

Northwestern Ohio is used to rain, but 2019 was one of Ohio’s wettest seasons in recent history. This higher-than-average precipitation caused many of the areas embankments to become saturated resulting in several slope failures. The slide started along US Route 24 in 2016. However, due to the heavy rain in 2019, the slide was exacerbated and a repair quickly became necessary. The repair project was awarded in March of 2020 and needed to be complete by December 2020.

The Challenge

One of the simplest solutions to repair most embankment slips is to increase the horizontal footprint, resulting in less of a slope for more stability. However, this solution was not viable for the slip on US Route 24 in Cecil, OH. Multiple variables, including property line demarcations, a restrictive right-of-way and existing drainage, made extending the base of the embankment for a more stable slope unviable. The original slope would need to be repaired but with greater shear strength since the in-situ soil exhibited inadequate (15 psi saturated) compressive strength of the native soil. Another challenge faced was the condensed timeline to complete the repair of the embankment slip.

The Solution

The Ohio Department of Transportation (ODOT) drew on their experience of using lime-based reagents to stabilize their subgrades quickly and cost-effectively. Having worked with Mintek’s experienced Customer Applications Specialists in the past, ODOT knew they could trust Mintek to assist with their project. ODOT and Mintek worked closely with the project’s contractor to determine the right solution to improve the stability of the embankment while meeting ODOT’s criteria. After evaluating all their options, and based on the success of prior stabilization projects utilizing Calciment® LKD, Calciment LKD was the chosen solution because of its ability to quickly transform the in-situ soil and provide the long-term, permanent strength gains needed to safely construct the steep slope of the embankment.

Implementation

Achieving the desired moisture content and compaction targets on site proved to be difficult, so Mintek was called for support. Calciment® LKD’s superior drying allowed the contractor to meet project timelines by drying the saturated soil to a workable moisture content while providing the long-term strength gains needed for this project. Mintek personnel provided field support that proved to be critical as pre-project testing was not possible due to the failing condition of the embankment and the need for a quick remedy. Mintek was able to quickly assess the site conditions, evaluate the soil and provide recommendations to improve the site conditions and accelerate the project schedule. The project was completed in November of 2020.

Results

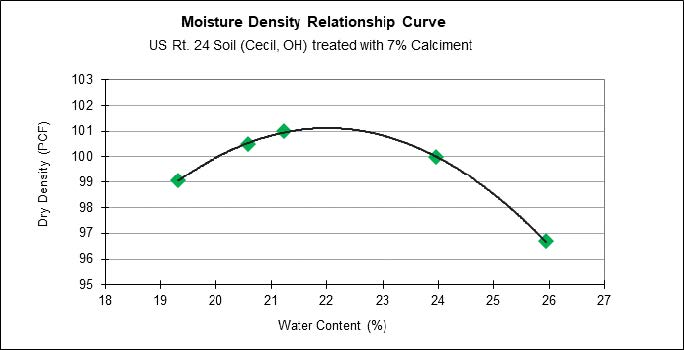

With Mintek’s support, at the end of the project, ODOT and the contractor achieved their desired targets. Field recommendations were confirmed with laboratory testing, which was completed at the Carmeuse Innovation Center’s soil laboratory, Mintek’s parent company. A five-point moisture-density relationship curve, commonly referred to as a Proctor curve, was performed on soil samples taken from the site. After Calciment® LKD was applyed, the Proctor curve showed the site conditions were in line with the ideal conditions producted in the lab. An optimum moisture content (OMC) of 22% was determined in the lab compared to the 21% OMC determined by a nuclear gauge in the field.

Per ODOT specification, the strength of soil stabilized with lime-based materials needed to be 50 psi greater than the untreated strength, with a minimum UCS of 100 psi. By treating the in-situ soil with 7% Calciment® LKD, the UCS of the soil was improved from 15 psi to 160 psi, far exceeding the strength specifications.

Lasting Success

The failed embankment along US Route 24 in Cecil, OH was successfully stabilized using Calciment. As a result, ODOT was able to keep costs low, utilize on-site soils, limit traffic restrictions, and provide a long-term solution. This project is one example of thousands that have successfully demonstrated the utility and effectiveness that lime-based products can offer to your soil related projects.

ODOT US Route 24 in Cecil, OH